close

Choose Your Site

Global

Social Media

Views: 0 Author: Site Editor Publish Time: 2024-10-31 Origin: Site

CNC (Computer Numerical Control) machines have transformed manufacturing processes across various industries by offering precision, efficiency, and versatility. Understanding the different types of CNC machines is crucial for industries looking to optimize their production capabilities. This article aims to provide an overview of the five most common types of CNC machines, highlighting their unique features and applications.

CNC machines are essential tools used in a wide range of manufacturing processes. The five common types of CNC machines include CNC mills, CNC lathes, CNC routers, CNC plasma cutters, and CNC laser cutters. Each machine serves specific functions and is designed for particular materials and applications, making them vital in modern production environments. Let’s delve into these types to understand their functionalities better.

CNC machines come in various forms, each tailored for specific tasks and industries. Below, we explore the five common types of CNC machines, detailing their operations, applications, and advantages.

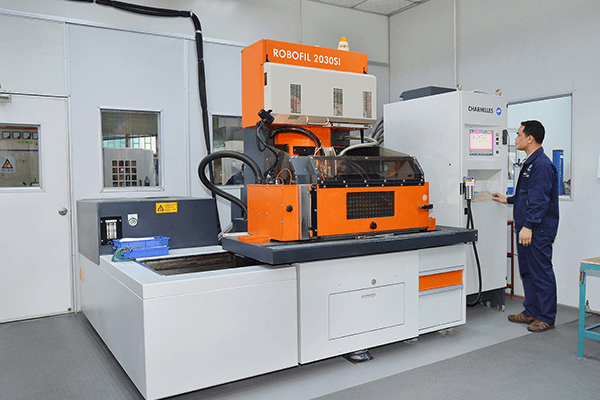

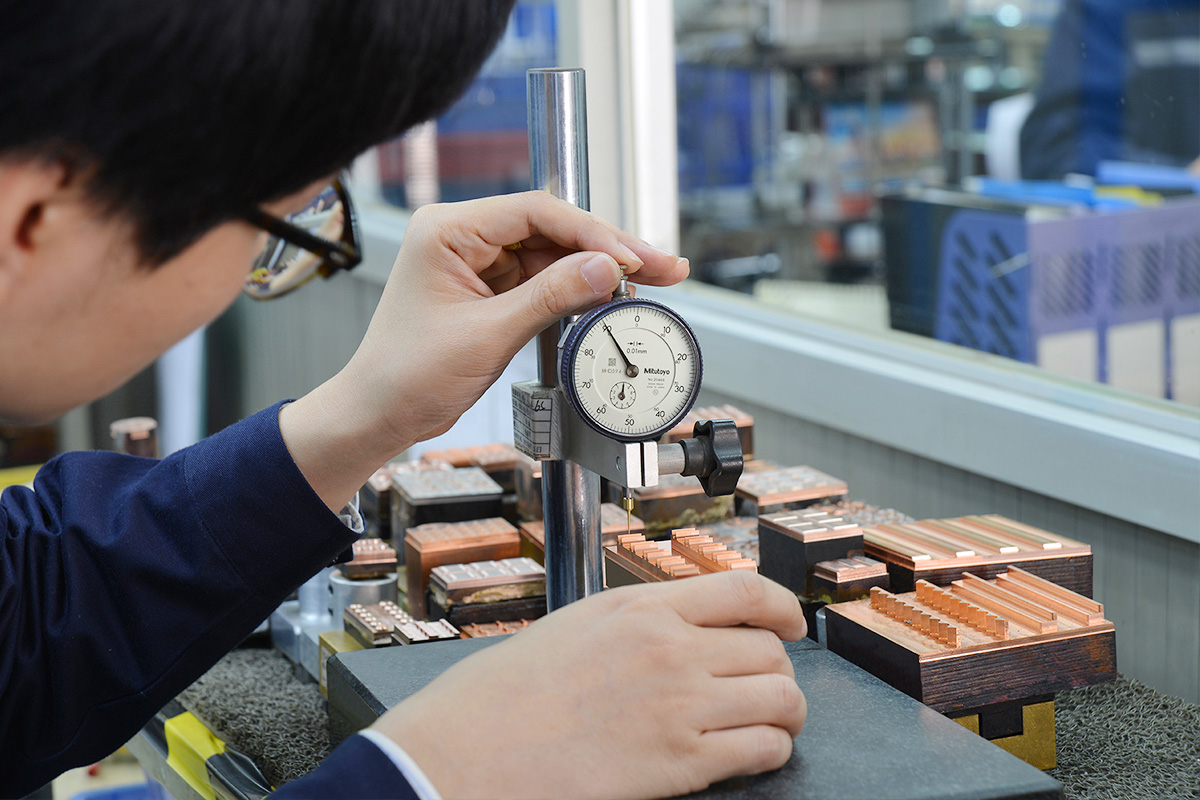

CNC milling machines are among the most versatile CNC tools available. They operate by removing material from a workpiece using rotary cutters. The workpiece is typically mounted on a table that can move in multiple directions, allowing for intricate designs and precise cuts.

CNC mills can perform a variety of operations, including drilling, tapping, and contouring. They are particularly useful for creating complex shapes and features, such as slots, holes, and intricate 3D contours. The ability to manipulate the spindle speed and feed rate allows operators to optimize cutting conditions for different materials, including metals, plastics, and wood.

These machines are widely used in industries such as aerospace, automotive, and medical device manufacturing, where precision and repeatability are crucial. CNC mills provide the flexibility needed to produce both high-volume parts and one-off prototypes, making them a staple in any modern machine shop.

CNC lathes are specialized machines primarily used for turning operations. They work by rotating a workpiece against a stationary cutting tool, allowing for the creation of cylindrical shapes, such as shafts, rods, and discs.

The operation of a CNC lathe is straightforward: as the workpiece spins, the cutting tool moves along the length of the material, shaping it into the desired form. CNC lathes can also perform additional functions, such as drilling and threading, making them versatile for various applications.

These machines are commonly found in industries like automotive and manufacturing, where precision and efficiency in producing round components are critical. The automation inherent in CNC lathes reduces the risk of human error and increases production speeds, making them a valuable asset for businesses looking to streamline their operations.

CNC routers are designed for cutting and shaping a wide range of materials, including wood, plastics, and soft metals. They operate similarly to CNC mills but are typically used for larger sheets of material and less intricate designs.

The primary function of a CNC router is to create flat or three-dimensional shapes through a process called subtractive manufacturing. The router moves along multiple axes to achieve complex cuts, engravings, and carvings. This capability makes CNC routers popular in woodworking, sign-making, and the production of custom furniture.

One of the notable advantages of CNC routers is their ability to handle large workpieces, making them ideal for projects that require cutting large sheets of material. Additionally, their versatility allows for a variety of applications, from prototyping to mass production.

CNC plasma cutters utilize a high-velocity jet of ionized gas (plasma) to cut through electrically conductive materials, such as steel, aluminum, and copper. These machines are particularly effective for cutting thick materials quickly and accurately.

In operation, the plasma cutter generates an electrical arc that ionizes the gas, creating plasma. This plasma is then directed through a focused nozzle, allowing for precise cutting. CNC plasma cutters can produce intricate designs and patterns, making them valuable in industries like metal fabrication, automotive, and construction.

One of the key benefits of CNC plasma cutting is its speed and efficiency, especially when working with thick materials. The process is also relatively cost-effective, making it a popular choice for businesses looking to optimize their cutting operations without sacrificing quality.

CNC laser cutters use focused laser beams to cut or engrave materials with exceptional precision. They are capable of working with various materials, including metals, plastics, wood, and fabrics.

The cutting process involves directing a powerful laser beam onto the material, which melts, burns, or vaporizes it, allowing for intricate designs and fine details. CNC laser cutters are known for their high accuracy and ability to produce clean edges, making them ideal for applications that require precision.

Industries such as signage, automotive, and electronics benefit significantly from CNC laser cutting technology. The versatility of these machines allows for a broad range of applications, from prototyping to large-scale production runs.

What materials can CNC machines work with?

CNC machines can work with a variety of materials, including metals, plastics, wood, and composites, making them versatile tools for different industries.

How do CNC machines improve manufacturing efficiency?

CNC machines enhance manufacturing efficiency by automating processes, reducing human error, and increasing production speed, allowing for higher output and lower costs.

Are CNC machines suitable for small businesses?

Yes, CNC machines are suitable for small businesses, enabling them to produce high-quality, precise parts without the need for large-scale operations, thus fostering growth and innovation.